-Process-

The most important thing for any of our projects is to eliminate miscommunication so that our clients can have a fun and enjoyable experience.

"The first step to getting the things you want out of life is this: Decide what you want."

-Ben Stein

Process

The process of designing a custom piece from wood is different with every client. However, whether a client has very specific ideas or a vague concept of what they want, every job comes down to creative problem solving.

At the initial meeting Brian will discuss goals, timeline, and potential issues for the project. If there is an architect or interior designer involved in the project, Brian will also consult with them so that his work will fit seamlessly into the overall goals and intent of the entire project.

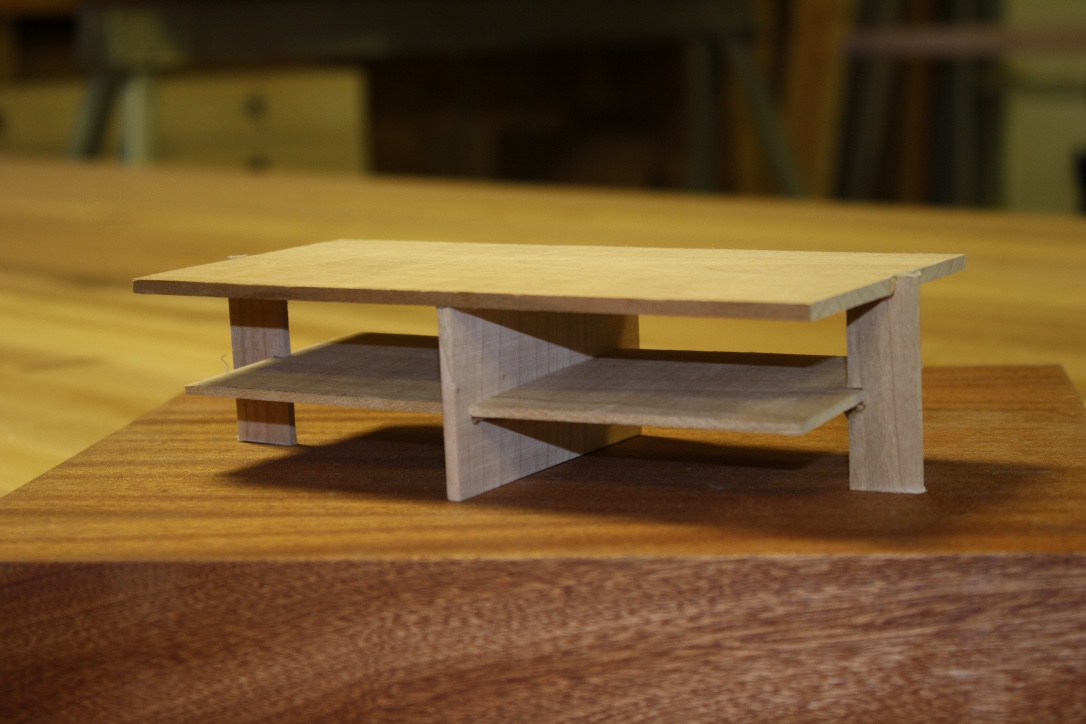

At the start of the design process, Brian will create sketches, small scale models, and/or technical drawings for the clients to review. Once the materials, finishes, joinery details, pricing, and schedule have been worked out, construction will begin. When working with cabinets or other built-in pieces, Brian will personally lead the on-site installation.

materials

It can be breathtaking to walk through the vast rows of rough-sawn lumber. Even if one were to only use native species, a full palette of colors, textures, and grains are available. Often, Brian finds himself unable to walk away from a stunningly unique specimen, even if he doesn't have an immediate use for it. He knows that eventually the perfect project will come along for these one of a kind pieces.

Another world of possibilities arises when recycled or reclaimed materials are used. Many times, character of reclaimed wood has been altered by wear, nail holes, or weather which can all add even more depth and patina to the board.

Brian has spent years developing a strong network of trusted wood sources. From small single man sawmill operators in Ohio and Kansas, to a large warehouse facility in Fort Collins.

Workshop

Laak Woodworks started in a 750 SF building in the backyard of Brian's home in old town Berthoud. Originally a farmer's tool shed, this small shop was meticulously laid out and comfortably allowed two people to work side by side. Since then the business has grown.

Laak Woodworks moved to a 3,000 SF shop. Still in Berthoud, this new location is equipped with 3 phase power which is better suited for industrial sized tools. Great care and deliberation has gone into the layout and outfitting of this space. However, despite the increase in scale, the shop still maintains the creative atmosphere that is at the heart of Laak Woodworks.